Orzen, Michael A.; Paider, Thomas A. (2015-10-14). The Lean IT Field Guide: A Roadmap for Your Transformation

Note: This blog post is made up of snippets of content from the book. They were my Kindle highlights. Buy the book here.

Foreward

The modern enterprise has a simple goal: create sustainable value i.e. make money now and in the long run. A principle challenge is leading and managing a very large number of people to achieve the goal. To achieve the goal most would agree we need:- Alignment from the top down on purpose and strategy

- Effective bottom up execution matched to the strategy

- Clear feedback enabling the adjustments needed to achieve the purpose

In brief Lean enables people at every level to understand and improve the part they play in achieving the goal. Employees define baseline work processes called "standard work," along with their performance metrics, problems and potential solutions called "counter-measures." Collaborative cycles of Plan, Do, Check, Adjust apply the scientific method to solve these problems using a simple "A3" document. Leaders "Go See" on "Gemba Walks" to understand what's happening and to mentor and learn how to support their people. All of this is big and visible. All of this happens at every level - not just the front line.

Lean leaders focus on the means as much as the ends because they see it to be the source of sustainable success.

Lean leaders focus on the means as much as the ends because they see it to be the source of sustainable success.

Chapter 1: Brief History of Lean

Chapter 2: Transformation Framework

The essence of standard work is to move away from people doing work their way (based on individual opinion and experience) to everyone working in a more consistent fashion. When everyone on the team abides by the standard, we begin to intentionally impact variability. Standard work serves as a snapshot of what good work looks like and a baseline from which improvement can happen.

Chapter 3 - 5: Purpose, Day Zero, Paradox of process

Purpose. So what is purpose? We like this definition: The reason for which something is done or created or for which something exists.A good purpose statement:

- Clear, concise, and clearly answers the question, Why?

- Inspires and motivates people to act: build, focus, provide, create, connect

- Memorable

Day Zero lays out the obvious get started stuff:

- Start small 10-100 based on org size

- Create "model line" or lines

- Executive buy in required or don't bother

- Getting executives, middle managers/directors, and associates working to visible standard work is a key focus

- Some good pragmatic reference materials in here

Process Paradox

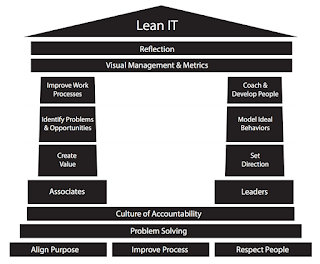

We must create a culture that views standards and processes as a way to challenge ourselves to find ways to improve the established routine and share that learning with others. This is why lean systems care more about how you get results than the results themselves. We want results that are repeatable, not one-time heroic efforts that only apply in the moment. Not everything can be predicted in IT, but just as importantly, not everything should be random and emergent. We can use processes and systems to create predictable and stable environments from which creativity and problem solving can flourish.This is at the foundation of our transformation model house, represented as Respect People, creating an environment that allows everyone to reach his or her full potential. That has to include creating a system that wipes out chaos, fear, and ambiguity in favor of one that allows learning and growth.

Standard Work:

"Think of standard work not as a common way we do things now and forevermore, but rather as adaptive standardization focused on continuously improving the current standard—standard because everyone is expected to know and follow the process, adaptive because standards will change as better ways are discovered."

Note - the book lays out what we did at Nationwide: one page diagram of process, one page of text, includes purpose, basic steps etc. E.g. Conduct Iteration.

Note - the book lays out what we did at Nationwide: one page diagram of process, one page of text, includes purpose, basic steps etc. E.g. Conduct Iteration.

"For leaders you’ll create a simplified document that outlines the cadence of activities and behaviors they will be held accountable for performing. There will be common elements among leaders in the organization, but each leader will have his or her own standard work, a personal version reviewed regularly with the boss. A few simple guidelines to help you create the documents include the following: 1. Focus on activities and behaviors that demonstrate leading with respect. 2. Make associate development and coaching a central theme. 3. The higher the level of the manager, the more strategic the focus will be."

"As much as possible, make coaching for performance and development of the frontline staff an activity that occurs at the gemba." (gemba refers to the place where value is created)

It is interesting how this exposition is different from Nationwide in implementation details, many lines, standard work defined based on observed team norms across the initial 7, how Kiazen worked...

Pretty good book so far. It seems to gloss over the level of "tell" leadership that was needed and appropriate based on where peoples skills and beliefs were.

Chapter 6: Plan Do Check Adjust

What is a problem:

A problem is a situation where- there is dissatisfaction by customers, employees, and/or suppliers in the way things work today; or

- a current process contains waste (non-value-added4 steps), an unacceptable degree of variation, or overburden; and

- no one has a clear and complete understanding of the cause(s) of the current condition.

This chapter is mostly about A3's!

Already familiar with this topic... Some key ideas:- Printed on big "A3" paper and updated using pencil

- A3's involve collaborating and building consensus with impacted stakeholders to agree on the problem and counter measures to try address the problem

- Value Stream Map's are typically central e.g. in "current state"

- Analyze the problem (don't just jump to a solution)

- Measure - ensure you can objectively describe the problem and evaluate if the countermeasures work - and be careful what you measure; watch for unintended consequences

- Plan your experiement and scheadule follow ups

- Fits into PDCA - iterate till your experiments and measures prove you've solved the problem

Start using A3s for two purposes:

- solving problems in frontline teams and in management, and

- creating and updating standard work and leader standard work.

Ends vs. Means

The main target is small step improvement based on experimentation; the results are a by-product.When we focus solely on the outcomes, especially in an environment that doesn’t value respect for people, we often reward sociopaths who see people as a consumable to achieve their goals. We both incent and reward the wrong behavior, which is a downward spiral compounding itself. By making the means the primary focus, results are achieved.

The Improvement Kata

The improvement kata is made up of five key questions that the coach asks the learner (the person trying to understand and solve the problem). These questions may seem simple, but they are extremely powerful in supporting people to expand and deepen the way they think about dealing with problems and making improvements:- What is the target condition?

- What is the actual condition right now?

- What obstacles are now preventing you from reaching the target condition? Which one are you addressing now?

- What is your next step/PDCA experiment?

- How quickly can we go and see what you have learned?

Chapter 7: Everything is Visible

For my agile friends: Big Visible Charts, Information Radiators etc.

From this point forward, make the commitment: If it’s important to the organization, it will be made visible. Strategy, process, quality, delivery, staffing, successes, and problems—everything; bring a level of transparency and trust to your company that can only exist in the visual workplace.

We are:

- Creating a shared understanding of the current situation and where we want to go in the future

- Drawing leadership to the gemba, where the real work happens

- Driving accountability and continuous improvement

Draw Leadership to the Gemba - Standardize only as required to keep communication flowing

Lean leaders have a direct connection to their associates and the work they deliver every day. In fact, the primary source of engagement for associates is their relationship with their direct manager. The manager plays the role of coach, teaching problem solving and developing each associate to his or her full potential. The connection is important for executives as well. We often see executives that are removed from the realities of daily work life and whose understanding of how strategy is being mobilized is based on fantasy. Connection to the day-to-day work, successes and failures, is critical in setting and executing strategic direction and vision.

But not all information made visible is needed by outsiders. Some of the visuals are only needed by a specific team or group of people. For example, for a team that has created rules for how members should act in the team space, the rules are likely only needed by the team. In this case, don’t micromanage the look and feel; leave it up to the team.

The first additional element to add to both the management and frontline systems is making visible your A3 process.

Create a section on your visual boards where anyone can recognize anyone else for a job well done. Post positive comments received from customers and co-workers. Publicly praise individuals when appropriate and take accountability to ensure that regular updates occur. Create an entry in every manager’s leader standard work to ensure that this remains a focus for the organization.

Define in standard work the process of keeping the visuals up to date. You can also build the standard work directly into the visual system and visually list who updates each section of the boards and when that update occurs. You can add features on the boards such as a last-updated indicator or updated by as your situation dictates as well.

No comments:

Post a Comment

Please no spam, advertisements, or unrelated personal discussions.